How Digitizing Decisions Affect Long-Term Production Efficiency

In the modern industrial landscape, digitizing decisions have become pivotal in shaping the long-term production efficiency of companies. As businesses strive to remain competitive, the integration of digital technologies into production processes is not just a trend but a necessity. The impact of these decisions can be profound, influencing everything from operational costs to product quality and market responsiveness.

The Role of Digitizing in Production

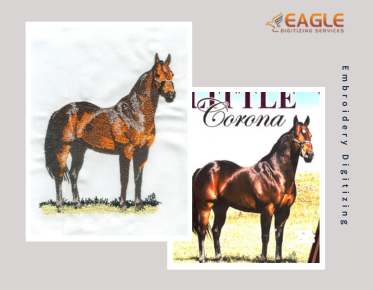

Digitizing in production involves converting traditional processes into digital formats, which can significantly enhance efficiency. This transformation allows for better data management, improved process control, and enhanced product quality. For instance, embroidery digitizing is a process where artwork is converted into a digital format that embroidery machines can read, leading to more precise and consistent outputs.

Cost Efficiency and Resource Management

One of the primary benefits of digitizing is cost efficiency. By automating processes, companies can reduce labor costs and minimize errors, which in turn decreases waste and rework. This is particularly evident in industries that rely heavily on precision, such as the textile and automotive sectors. Moreover, digitizing allows for better resource management by providing real-time data on inventory levels, production rates, and equipment status.

Enhancing Product Quality

Digitizing decisions directly impact product quality. By using digital tools, companies can ensure that their products meet high standards consistently. For example, in the embroidery industry, digitizing services ensure that designs are accurately translated into stitch files, which helps maintain the integrity of the original artwork. Companies like Eagle Digitizing offer specialized services that focus on minimizing thread breakage and ensuring smooth sew-outs, which are crucial for maintaining product quality【4:0†source】.

Speed and Flexibility in Production

The speed of production is another area where digitizing decisions play a critical role. Digital processes allow for faster turnaround times, enabling companies to respond quickly to market demands. This flexibility is essential in today's fast-paced business environment, where consumer preferences can change rapidly. For instance, Eagle Digitizing provides quick turnaround times, often completing orders within 24 hours, which helps businesses stay agile and competitive【4:1†source】.

Data-Driven Decision Making

Digitizing also facilitates data-driven decision-making. By collecting and analyzing data from digital processes, companies can gain insights into their operations, identify areas for improvement, and make informed decisions. This capability is invaluable for long-term strategic planning and can lead to more sustainable business practices.

Challenges and Considerations

Despite the numerous benefits, digitizing decisions come with challenges. The initial investment in digital technologies can be significant, and there is a learning curve associated with new systems. Companies must also consider data security and the potential for technology obsolescence. However, with careful planning and execution, these challenges can be managed effectively.

The Future of Digitizing in Production

Looking ahead, the role of digitizing in production is set to expand. As technologies such as artificial intelligence and the Internet of Things continue to evolve, they will offer new opportunities for enhancing production efficiency. Companies that embrace these advancements will likely gain a competitive edge, driving innovation and growth in their industries.

In conclusion, digitizing decisions are crucial for long-term production efficiency. By enhancing cost efficiency, product quality, and production speed, these decisions can significantly impact a company's success. As the digital landscape continues to evolve, businesses must stay informed and adaptable to leverage the full potential of digitizing technologies.