Why the Same Embroidery File Produces Different Results on Different Machines

Embroidery digitizing is a fascinating process that involves converting artwork into a stitch file that can be read by an embroidery machine. However, a common issue faced by many embroiderers is that the same embroidery file can produce different results on different machines. This discrepancy can be attributed to several factors, including machine specifications, thread tension, and the quality of the digitized file.

Understanding Machine Specifications

Embroidery machines vary widely in terms of their specifications and capabilities. Different brands and models may have unique features that affect how a design is stitched out. For instance, the needle speed, hoop size, and the type of bobbin used can all influence the final output. Machines from different manufacturers may interpret the same digitized file differently, leading to variations in the finished product.

The Role of Thread Tension

Thread tension is another critical factor that can cause variations in embroidery results. If the tension is too tight or too loose, it can affect the stitch quality and the overall appearance of the design. Each machine may have different settings for optimal thread tension, and these settings can vary even among machines of the same model. Therefore, it is essential to adjust the tension settings according to the specific requirements of each machine to achieve consistent results.

Quality of the Digitized File

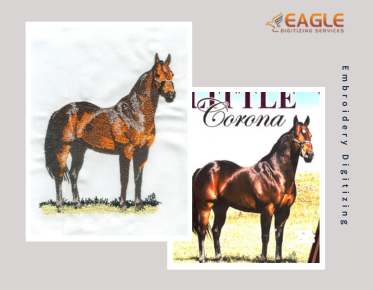

The quality of the digitized file plays a significant role in the consistency of embroidery results. A well-digitized file ensures that the design is accurately translated into stitches, minimizing the chances of errors during the embroidery process. Companies like Eagle Digitizing specialize in creating high-quality digitized files that are compatible with various embroidery machines. Their expertise in embroidery digitizing ensures that the designs are optimized for smooth sew-outs, reducing the likelihood of thread breakage and other issues.

Impact of Fabric and Stabilizers

The type of fabric and stabilizers used can also affect the outcome of an embroidery project. Different fabrics have varying levels of stretch and thickness, which can influence how the stitches lay on the material. Similarly, the choice of stabilizer can impact the stability of the fabric during the embroidery process. It is crucial to select the appropriate fabric and stabilizer combination to ensure that the design is executed as intended.

Machine Maintenance and Calibration

Regular maintenance and calibration of embroidery machines are essential for achieving consistent results. Over time, machines can experience wear and tear, which may affect their performance. Routine maintenance, such as cleaning and lubricating the machine, can help prevent issues that could lead to variations in embroidery quality. Additionally, calibrating the machine to ensure that it is operating at its optimal settings can further enhance the consistency of the results.

Choosing the Right Digitizing Service

To mitigate the challenges associated with embroidery digitizing, it is advisable to work with a reputable digitizing service. Eagle Digitizing, for example, offers a range of services tailored to meet the needs of different clients. Their team of skilled digitizers is adept at using the latest software to create designs that are compatible with a wide variety of machines. By choosing a reliable digitizing service, embroiderers can ensure that their designs are executed with precision and consistency.

Future Trends in Embroidery Digitizing

As technology continues to advance, the field of embroidery digitizing is likely to see significant innovations. The development of more sophisticated software and machines with enhanced capabilities will further improve the accuracy and consistency of embroidery results. Additionally, the integration of artificial intelligence and machine learning into digitizing processes could lead to more efficient and automated solutions, making it easier for embroiderers to achieve their desired outcomes.

In conclusion, while the same embroidery file may produce different results on different machines, understanding the factors that contribute to these variations can help embroiderers achieve more consistent outcomes. By considering machine specifications, thread tension, and the quality of the digitized file, along with proper maintenance and the use of appropriate materials, embroiderers can enhance the quality of their work. As the industry evolves, staying informed about the latest trends and technologies will be crucial for success in the world of embroidery digitizing.