How to use a Yudu screen printing machine?

Screen printing is a time-honored technique that can produce vibrant and durable print results. One of the popular tools for home and small business screen printing is the Yudu screen printing machine. This user-friendly device has made screen printing more accessible to hobbyists and professionals alike.

Understanding the Yudu Screen Printing Machine

The Yudu screen printing machine is designed to streamline the screen printing process, making it easier for non-professionals to create high-quality prints. With its comprehensive features, this machine reduces the complexity of traditional screen printing. Unlike conventional methods, Yudu integrates elements such as exposure, drying, and printing into a single platform.

Step-by-Step Guide to Using the Yudu Machine

1. Preparing Your Design

Before you begin screen printing, you need to have a design ready for transfer. Ensure that your design is thoroughly cleaned up and scaled correctly. You can use software to create a digital version of your design. For optimal results, consider using vector art conversion services to transform bitmap designs into crisp, scalable vector files.

2. Setting up the Screen

Begin by placing the emulsion sheet (provided with the Yudu kit) over the screen. The emulsion is a light-sensitive material that will allow you to "burn" your design onto the screen. Make sure to apply the emulsion evenly and let it dry completely in a dark area to avoid premature exposure.

3. Exposing the Screen

Once the emulsion is dry, position your design on the exposure table. The Yudu machine comes with a built-in exposure unit. Lay your screen with the dry emulsion coated side facing down over your design. Seal the lid and start the machine to expose the screen. The light will harden the emulsion, leaving only the design areas clear for ink to pass through.

4. Washing the Screen

Next, wash the screen using a gentle water spray. The non-exposed emulsion will dissolve and wash off, leaving the precise areas where ink will pass through. Make sure all excess emulsion is removed and that your design is clearly visible on the screen.

5. Preparing to Print

Once the screen is clean and dry, you are ready to print. Place your textile product on the platen, ensuring it's flat and secure. Align your screen over the item and secure it in place. Yudu's design makes this step straightforward, helping to align designs accurately and consistently.

6. Applying Ink

Select the appropriate ink for your material. Yudu supplies non-toxic inks suitable for various fabrics. Apply the ink to the top of your screen and use the squeegee to pull the ink evenly across the screen. Consistent pressure is key to ensuring a uniform print.

7. Curing the Print

After printing, it's crucial to cure the ink to ensure durability. Use the Yudu machine’s drying feature or a separate heat source like a heat press. Allow the print to dry completely before handling the garment.

Best Practices for Maintenance

Maintaining your Yudu screen printing machine is vital for consistent print quality and longevity. After each use, thoroughly clean screens and tools to prevent ink from drying and hardening. Regularly inspect the machine for any mechanical issues and address them promptly. The machine's exposure unit and platen should be kept dust-free to ensure precise exposure and consistent print registration.

Applications and Benefits

The Yudu screen printing machine is ideal for small businesses, art enthusiasts, and anyone interested in creating custom printed t-shirts, posters, and more. Its portability and ease of use make it a valuable tool for those starting in screen printing. Moreover, Yudu provides an engaging way to bring one's creative designs to life without requiring extensive technical skills or facilities.

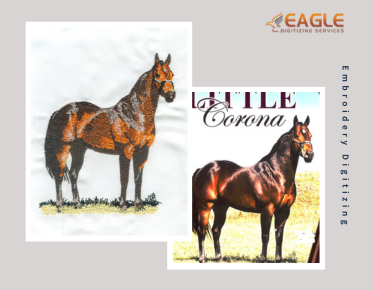

In addition to fabric, the Yudu machine can be used on various substrates, expanding its utility beyond apparel. This versatility is enhanced if one uses quality vectorized designs. For those seeking professional vectorization, companies like Eagle Digitizing offer vector art services that can convert intricate designs into clean and scalable vector files, ensuring the best possible results when printing.

Expanding Your Creative Business

For those considering screen printing as a business venture, the Yudu machine offers a cost-effective entry point. By mastering this equipment and understanding design conversion, you could provide local businesses, schools, and organizations with unique and personalized printing solutions. Considering the potential of custom vectors, convert art to vector for niche branding and bespoke designs can be lucrative.

As the screen printing industry continues to grow, innovations in vector-based designs and digital tools like the Yudu machine promise to broaden possibilities. Whether for hobby or business, mastering these skills offers exciting future possibilities for creative expression and enterprise expansion.