How much detail can screen printing achieve?

Screen printing has been a staple in the world of printmaking and merchandise for decades. Known for its versatility and durability, it's a preferred method for printing on a variety of materials, including fabrics, plastics, and metals. But when it comes to the detail that screen printing can achieve, there's often a question about its capabilities and limitations.

Understanding Screen Printing

Screen printing, also known as silk-screen printing, involves using a mesh screen to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. This technique can create vibrant colors and prints that are difficult to achieve through other methods. However, the level of detail that screen printing can achieve largely depends on several factors, such as the mesh count of the screen, the type of ink used, and the surface onto which the ink is being printed.

Factors Affecting Detail in Screen Printing

The detail in screen printing is influenced by multiple aspects:

- Mesh Count: The number of threads per inch in the screen fabric is known as the mesh count. Higher mesh counts produce more detail as the ink passes through smaller openings, allowing for finer lines and dots.

- Ink Viscosity: Thinner inks will spread and run, which can blur finer details, while thicker inks can be controlled more precisely.

- Substrate Texture: Smooth surfaces hold finer detail better than rough-textured surfaces, which can scatter the ink.

Advancements in Screen Printing Technology

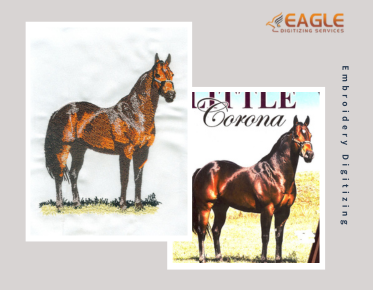

With advancements in technology, screen printing can now compete with digital printing to a certain extent in terms of detail and quality. Modern techniques have enhanced its precision, allowing for more complex designs and color separations. Professional services, like those offered by Eagle Digitizing, specialize in converting intricate designs into scalable vector graphics, which are ideal for screen printing purposes.

Vector Graphics and Screen Printing

Vector graphics are crucial for achieving high detail in screen printing. By utilizing vector graphics, each element of the image can be resized and adjusted without losing clarity. Companies like Eagle Digitizing provide services to convert raster images to vectors, enhancing the capability of screen printers to achieve finer details. This service includes color separation and meticulous line optimization, ensuring that prints are sharp and vibrant.

Practical Applications

Among the practical applications, screen printing is extensively used in creating promotional products, apparel, and signage. The need for detailed imagery can be satisfied through the use of high-quality vector conversions. For instance, brands looking to market their products with elaborate logos and detailed imagery rely on vector services to deliver top-notch prints.

Comparing Screen Printing to Other Methods

While digital printing is often hailed for its exceptional detail and full-color capabilities, screen printing holds its ground with superior color saturation and durability. Additionally, for runs above a certain quantity, screen printing can be more cost-effective, particularly when utilizing vectorized designs that maximize detail without increasing costs substantially.

Future Prospects of Screen Printing

Looking ahead, the future of screen printing is promising. With ongoing advancements in mesh technology and ink formulations, the ability to capture even finer details is improving. Integrating digital technologies with traditional screen printing processes may further enhance this capability, providing a hybrid solution that leverages the strengths of both methodologies.

As more industries seek sustainable printing solutions, the adaptability and durability of screen printing will continue to make it a favorable option. Businesses focusing on sustainable practices can also find opportunities in screen printing by utilizing water-based inks and eco-friendly screen materials.

Conclusion: A Craft Still in Evolution

Screen printing, with the aid of vector graphics, remains a viable and vibrant method for producing detailed prints on various substrates. As technology continues to evolve, so does the potential for this time-honored technique, balancing it delicately between tradition and innovation. By embracing these advancements, screen printing can achieve remarkable detail, meeting modern standards and expectations. How might these improvements influence your choice between screen and digital printing, especially in a creatively competitive market?

.png)