How do you screen print a custom t-shirt?

Screen printing, a popular method for creating custom t-shirts, involves transferring ink onto a substrate using a mesh screen. The technique is known for producing vibrant designs that can withstand wash and wear over time. But how exactly do you screen print a custom t-shirt? Below, we will explore the necessary steps, from preparing your design to finishing touches.

Understanding the Screen Printing Process

Before diving into screen printing, it's essential to grasp the procedure's basic components. The process involves a stencil, screen, squeegee, and ink. Each color in your design requires a separate screen and stencil. The process begins by coating the screen with a light-sensitive emulsion. Once dry, the design is placed on the screen, and exposed to light, creating a stencil of the image.

Step 1: Prepare Your Design

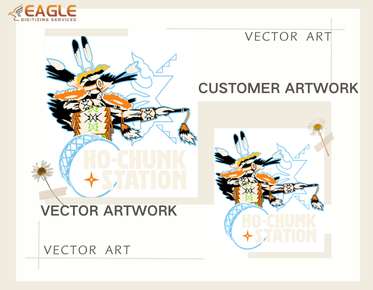

The first step in screen printing is to create a design. If your design is digital, ensure it is vectorized. Vectorization helps in maintaining the design's quality when enlarging or reducing it. For professional vectorization services, you might consider companies like Eagle Digitizing, which offer comprehensive services from raster to vector conversion.

Step 2: Set Up the Workstation

Setting up a screen printing station requires space for a press, which can be a simple tabletop version or a more advanced multi-color press. Make sure you have ample workspace for laying out screens and drying printed t-shirts. It's vital to ensure that your workstation is well-ventilated and equipped with all necessary materials, including inks, emulsion, and a light source.

Step 3: Creating the Screen

To create the screen, coat it with a photo emulsion. Once it’s dry, place the transparency of your design on the screen and expose it to light. The areas of the emulsion that are not covered by the design will harden, forming a stencil.

Printing Your T-shirt

Step 4: Preparing to Print

Once the screen is ready, place the t-shirt on the printing board and position the screen on top of it. Ensure the screen is correctly aligned with the t-shirt to avoid misprints. Apply the ink to the top of the screen and use a squeegee to spread the ink across the screen. The ink will pass through the open areas of the stencil and onto the shirt.

Step 5: Curing the Ink

After printing, the t-shirt must be cured to set the ink. This can be done using a heat press or a commercial dryer. Proper curing is vital to ensure the design's longevity on the fabric. Curing under the right temperature prevents the ink from cracking or peeling.

Enhancing Your Screen Printing with Digital Help

Eagle Digitizing offers services such as vector art conversion, providing crisp designs that are ideal for screen printing. With their quick turnaround times and skilled team, they ensure a seamless process ready for print. Their expertise in vectorizing images ensures your designs are print-ready, enhancing the overall print quality.

Step 6: Finishing Touches

After the ink has cured, inspect the t-shirt for any imperfections. Remove any excess ink smudges and trim any hanging threads. The completed t-shirt should be ready for packaging and distribution to your eager customers.

The Future of Screen Printing

As technology continues to evolve, so does the screen printing industry. Digital tools and software advancements simplify the design process, offering precision and efficiency. By integrating innovative solutions, like those provided by companies specializing in vector and digitizing services, businesses can remain competitive in the increasingly dynamic market. The blend of traditional techniques and digital enhancements will likely continue to drive the industry's growth.

.png)