Basic Steps in Constructing a Screen Printing Frame from Wood and Polyester Mesh

Screen printing is a versatile and popular method for transferring designs onto various surfaces, from textiles to posters. One of the essential components of this process is the screen printing frame, which holds the mesh that transfers the ink onto the substrate. Constructing a screen printing frame from wood and polyester mesh is a straightforward process that can be done with basic tools and materials. This guide will walk you through the essential steps to create a durable and effective screen printing frame.

Materials and Tools Required

Before you begin, gather the necessary materials and tools. You will need:

- Wooden strips (preferably pine or another softwood) for the frame

- Polyester mesh

- Wood glue or screws

- Staple gun and staples

- Sandpaper

- Measuring tape

- Saw (hand saw or power saw)

- Clamps

Step 1: Cutting the Wood

Start by cutting the wooden strips to the desired size of your frame. The size will depend on the size of the prints you intend to make. Ensure that the corners are cut at 45-degree angles to allow for a snug fit when assembling the frame. Use sandpaper to smooth out any rough edges, which will help the frame fit together more precisely and prevent splinters.

Step 2: Assembling the Frame

Once the wood is cut and sanded, it's time to assemble the frame. Apply wood glue to the mitered edges and join them together to form a rectangle. Use clamps to hold the frame in place while the glue dries. For added strength, you can also use screws to secure the corners. Make sure the frame is square by measuring the diagonals; they should be equal.

Step 3: Attaching the Polyester Mesh

After the frame is assembled and the glue has dried, it's time to attach the polyester mesh. Cut the mesh slightly larger than the frame to allow for stretching. Lay the mesh over the frame and use a staple gun to secure it in place, starting from the center of each side and working your way outwards. Stretch the mesh tightly as you staple to ensure a taut surface, which is crucial for achieving sharp prints.

Step 4: Finishing Touches

Once the mesh is securely attached, trim any excess material from the edges of the frame. Inspect the frame for any loose staples or areas where the mesh may not be fully secured. Make any necessary adjustments to ensure the mesh is evenly stretched and securely fastened.

Step 5: Preparing for Use

Before using your new screen printing frame, it's a good idea to test it with a small amount of ink to ensure there are no leaks or issues with the mesh tension. If everything looks good, your frame is ready for use in your screen printing projects.

Considerations for Quality and Durability

When constructing a screen printing frame, the quality of the materials and the precision of the assembly are crucial for achieving the best results. Using high-quality polyester mesh and ensuring the frame is square and sturdy will contribute to the longevity and effectiveness of your screen printing setup. Additionally, maintaining your frame by cleaning it after each use and storing it properly will help extend its lifespan.

Exploring Further Techniques

Screen printing is a craft that offers endless possibilities for creativity and customization. Once you have mastered the basics of constructing a screen printing frame, you can explore advanced techniques such as multi-color printing, using different types of inks, and experimenting with various substrates. The skills you develop in building and maintaining your screen printing equipment will serve as a foundation for more complex projects and artistic endeavors.

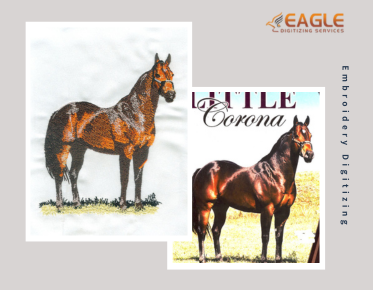

As you continue to refine your screen printing skills, consider exploring other related areas such as embroidery digitizing and custom vector art services. These techniques can complement your screen printing projects and expand your creative capabilities. Whether you're a hobbyist or a professional, the world of screen printing offers a wealth of opportunities for artistic expression and innovation.

.png)