Why Do Print Shops Reject Vector Files? 5 Common Reasons

In the digital age, vector files play a crucial role in the printing process. They provide clean and scalable graphics that are essential for producing high-quality printed materials. However, there are times when print shops may reject these files, leading to delays and potential frustration for clients. Understanding these reasons can help designers and clients alike to avoid pitfalls and ensure a smoother printing process.

Reason 1: Incorrect File Format

One of the most common reasons a print shop might reject a vector file is due to incorrect file formats. Print shops typically require specific vector file formats such as PDF, AI, or EPS. Using uncommon or non-standard formats might lead to compatibility issues. It's crucial to adhere to the file format requirements stipulated by the print shop.

Reason 2: Missing Fonts

Vector files often include text elements that require specific fonts installed on a print shop’s production system. If these fonts are missing or unavailable, the text may not render correctly, resulting in rejected files. A common recommendation is to convert text into outlines before submitting vector files. This ensures that the text remains consistent regardless of the fonts available on the print shop’s computers.

Reason 3: Incomplete Artwork

Print shops may reject vector files if the artwork is incomplete. This can happen if certain layers or elements have not been fully converted into vector format. It's imperative to double-check the vector file for completeness and accuracy. Utilizing services like online vector graphic services ensures that vector files are prepared according to industry standards.

Subsection: Checking Vector Completeness

Before submitting a vector file, one should thoroughly review all elements and ensure there aren't stray points or unconverted pixel elements. This extra step can prevent unnecessary rejections and reduce production time delays.

Reason 4: Poor Quality Conversion

Vector files converted from raster images might suffer from poor quality if not processed correctly. This can result in jagged lines or incorrect scaling, prompting rejection by print shops. Utilizing reliable image vectorization services can enhance the quality of the conversion and ensure that the graphic meets the required standards.

Reason 5: Embedded Images

Sometimes, vector files include embedded raster images, which contradicts the purpose of submitting a vector file. These embedded images can affect the print quality and scalability of the artwork. Print shops prefer fully vectorized files or separate the raster images to maintain the integrity of the project.

Using Embedded Images Wisely

While embedding images in a vector file might seem convenient, it can lead to complications during printing. A best practice is to provide linked images separately along with the vector file, ensuring that they maintain the resolution required for the final print.

Understanding these common reasons can improve communication with your print shop and enhance the overall production process. Utilizing professional vector conversion services can save time and alleviate potential issues related to file rejections.

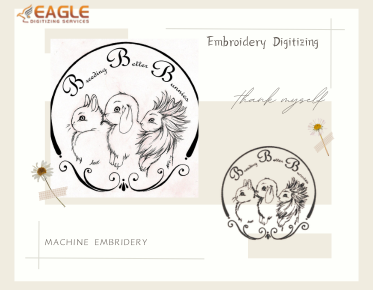

As the value of digital design continues to rise, so does the demand for efficient digital conversion services. Companies like Eagle Digitizing exemplify this trend by offering comprehensive solutions for vector file preparation. From raster to vector conversion to intricate vector logos and image edits, their services guarantee a professional standard that's ready for any print task. They cater to a diverse set of needs across different business types, ensuring that every project, no matter how unique, is handled with precision and care.

The future of digital printing is bright, with technology continuing to evolve, offering more robust solutions for designers and print shops alike. By keeping abreast of these developments and adhering to industry best practices, businesses can continue to produce top-notch print materials with greater efficiency and flair.