How do you screen print a custom t-shirt?

Introduction to Screen Printing

Screen printing, a versatile and popular method for creating custom t-shirts, involves pressing ink through a stenciled mesh screen to apply a design onto fabric. From team uniforms to promotional products, screen printing offers vibrant, long-lasting colors and sharp details, making it a go-to technique for high-volume printing. Whether you're a hobbyist or a business, mastering this method can set you apart in the competitive textile market.

Creating Your Design

Design Preparation

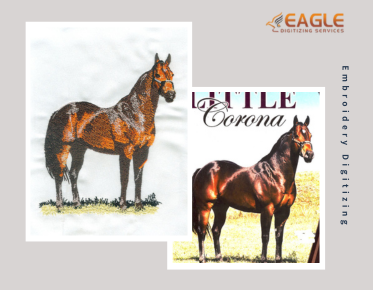

The first step in screen printing a custom t-shirt is creating your design. Most designs start as digital images, which might need to be converted into vector format for the best print quality. Vector art provides clean, scalable designs and is essential for color separation processes that are crucial in screen printing. Companies like Eagle Digitizing specialize in converting raster images into vector art services, ensuring crisp and precise prints without pixelation.

Setting Up Color Separation

Once you have your design ready, the next step involves separating it into different colors. Each color in your design will need a separate screen, as they will be layered during the printing process. This step is crucial for ensuring that the colors in your design do not overlap or blend incorrectly. Utilizing professional services that offer vector color separation can save time and ensure accuracy.

Preparing the Screen

Coating the Screen

Before you can transfer your design onto a t-shirt, you need to coat your screen with a light-sensitive emulsion. This emulsion hardens to form a stencil of your design once exposed to light. Make sure to apply a smooth, even coat to ensure a precise print. After applying, let the emulsion dry in a dark room to prevent premature exposure.

Transferring the Design

Place a transparency of your design on the screen and expose it to bright light. The light will harden the emulsion except where your design is blocking it, creating a stencil. After exposure, rinse the screen with water; the areas that were protected by your design will wash away, leaving a stencil of your design.

Printing the T-Shirts

Setting Up the Station

Once your screen is prepared, set it up on a printing press. This can be a manual or automatic press, depending on your production scale. Secure the screen tightly to ensure no shifting during printing. It’s also important to line up the t-shirt so your design prints in the correct position.

Applying the Ink

Choose your ink type based on the fabric of your t-shirt and the desired effect. Using a squeegee, pull the ink across the screen to press it through the open areas of the stencil. This action transfers your design onto the fabric. You may need several passes to ensure coverage, especially for dark garments.

Curing the Ink

After printing, the ink needs to be cured to set it permanently onto the shirt. This usually involves running the shirts through a conveyor belt dryer. The heat from the dryer cures the ink, making the design durable and washable.

Finishing Touches

Quality Control

Check each t-shirt for print quality, ensuring that all prints match the specified design details and colors. This process might include examining for smudges, color alignment, and ensuring consistent print positioning.

Packing and Distribution

Once your shirts pass quality control, they are ready for packaging and distribution. Consider the packaging materials and methods that best suit your brand. For example, eco-friendly packaging can enhance your brand image.

The Role of Professional Services

For those who seek professional precision and quality in custom screen printing, relying on services like vector art conversion can be invaluable. Companies like Eagle Digitizing offer services that are tailored for businesses ranging from small print shops to large promotional firms.

Eagle Digitizing's services extend beyond simple conversion; they provide comprehensive art services, including raster to vector conversion, vector logo designs, and image retouching, which are essential for creating detailed and high-quality prints on textiles.

Embracing the Future of Screen Printing

Screen printing continues to evolve with advancements in technology and techniques. The future of screen printing lies in integrating digital technology to streamline processes, reduce waste, and offer more customized services. As the industry grows, leveraging technologies such as digital inkjet and hybrid printing systems can unlock efficiency and creativity. What innovations will become mainstream, and how might they reshape the way we produce and consume custom apparel? These questions will guide the industry as it moves forward.

.png)

.png)