The Ideal Lighting for Optimizing Screen Printing Results

Screen printing is a popular method employed in many industries, from apparel to posters, because of its ability to produce vibrant colors and long-lasting prints. To achieve the best results in screen printing, appropriate lighting is crucial. Good lighting not only ensures that screens are correctly exposed but also helps in accurately aligning films and checking the colors and details of the print. This blog delves into the types of lighting that can enhance screen printing processes.

Understanding Screen Printing Exposure

Exposure is the process of using light to harden the emulsion on the screen where no image is present. During exposure, the light must pass evenly through the screen to develop a crisp image. The most common lights used in this phase are UV lights. UV light is effective because it can quickly cure the emulsion, leading to more precise and durable stencils. For optimal results, many talented vector art services online advise a UV exposure unit for uniformity and efficiency.

The Role of Natural and Artificial Lighting

While UV exposure is pivotal during the screen development phase, having a well-lit workspace is equally important. Natural daylight or full-spectrum fluorescent lamps are recommended for general tasks such as screen washing and inspection. These lights simulate daylight and allow for a more accurate inspection of colors and designs. Effective lighting can highlight potential problems in the emulsion application, ensuring quality control before the print run begins.

Advantages of Using LED Lights

Innovations in lighting technology have introduced LED lights as a viable option for screen printing. LEDs are cost-effective, energy-efficient, and produce less heat, which protects the emulsion from premature curing. The precise lighting control offered by LEDs improves the accuracy during the alignment of film positives. Furthermore, LEDs have a longer lifespan, reducing the frequency of replacements and maintenance.

Why Lighting Matters in Color Proofing

Color proofing is an essential aspect of screen printing, and lighting plays a critical role in this process. Proper lighting ensures colors appear as they do in natural daylight. Fluorescent tubes with a CRI (Color Rendering Index) of 90 and above are preferred for their ability to render colors accurately. This ensures that the final output matches the client's expectations and specifications. Vector conversion services professionals often stress the importance of precise lighting for maintaining consistency in large printing projects.

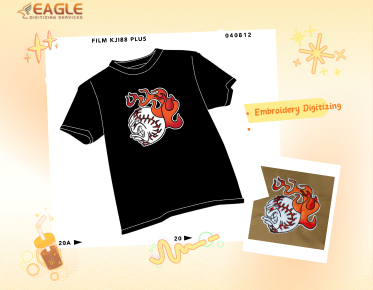

Eagle Digitizing Services

When it comes to screen printing and associated design services, Eagle Digitizing is a leader in the field. They offer comprehensive solutions including detailed vectorizing, which allows for high-quality print output. Their services extend beyond basic conversion; they also offer advanced color separations essential for screen printing. This ensures that each color layer is well-defined, facilitating a smoother production process.

Choosing the Right Lighting for Your Setup

The choice of lighting largely depends on the scale and specific needs of your screen printing operation. For instance, small scale businesses or hobbyists might find compact fluorescent lamps sufficient, while larger operations might invest in high-intensity UV lamps for faster and more consistent results. Always remember that regardless of the lamp type, positioning and evenness of light exposure are vital for accurate transfer of designs.

Looking Ahead: Technological Advances in Lighting

The future of screen printing lighting looks promising with ongoing advancements in LED technology and smart lighting systems. These innovations are set to further improve energy efficiency and control precision. Exploring smart systems that adjust light intensity according to specific tasks can optimize the screen printing process even further, aligning with the growing demand for environmentally friendly solutions. As the printing industry evolves, staying updated with these lighting technologies could be a game-changer for businesses striving for excellence.