Key to Enhancing Productivity: The Application of Embroidery Services and Vector Art Design in the Manufacturing Industry

In the ever-evolving landscape of the manufacturing industry, productivity is a key driver of success. Companies are constantly seeking innovative ways to enhance efficiency and output. One such method that has gained significant traction is the application of embroidery services and vector art design. These techniques not only add aesthetic value but also streamline production processes, offering a competitive edge in the market.

The Role of Embroidery Services in Manufacturing

Embroidery services have long been associated with the textile and apparel sectors, but their application extends far beyond these industries. In manufacturing, embroidery can be used to create intricate designs on a variety of materials, from fabrics to metals. This versatility makes it an invaluable tool for branding and customization, allowing companies to offer unique products that stand out in the marketplace.

Enhancing Brand Identity

One of the primary benefits of using embroidery in manufacturing is its ability to enhance brand identity. By incorporating company logos and designs into products, businesses can create a strong visual presence that resonates with consumers. This is particularly important in industries where brand recognition is crucial, such as fashion and consumer goods.

Streamlining Production Processes

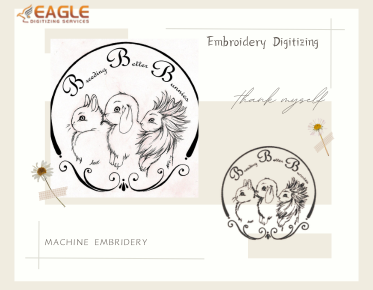

Embroidery services also contribute to more efficient production processes. With advancements in technology, embroidery machines can now produce complex designs with minimal human intervention. This reduces the time and labor required for production, leading to cost savings and increased output. Companies like Eagle Digitizing offer embroidery digitizing services that convert artwork into stitch files, ensuring precision and consistency in every piece.

Vector Art Design: A Game Changer

Vector art design is another powerful tool in the manufacturing industry. Unlike raster images, vector graphics are composed of paths defined by mathematical expressions, allowing them to be scaled infinitely without losing quality. This makes vector art ideal for creating detailed designs that require precision and clarity.

Applications in Product Design

Vector art is widely used in product design, particularly in industries such as automotive and electronics. It enables designers to create intricate patterns and layouts that can be easily modified and adapted to different products. This flexibility is essential for manufacturers looking to innovate and stay ahead of the competition.

Improving Production Efficiency

By using vector art, manufacturers can improve production efficiency. The scalability of vector graphics means that designs can be applied to various products without the need for extensive rework. This reduces production time and minimizes errors, leading to higher quality products and satisfied customers.

Integrating Embroidery and Vector Art for Maximum Impact

The true potential of embroidery services and vector art design is realized when these techniques are integrated. By combining the precision of vector art with the aesthetic appeal of embroidery, manufacturers can create products that are both visually stunning and functionally superior. This integration is particularly beneficial in industries such as fashion, where design and functionality are equally important.

Case Study: Eagle Digitizing

Eagle Digitizing is a leader in the field of embroidery digitizing, offering a range of services that cater to various industries. Their expertise in converting artwork into digital form allows them to deliver high-quality designs that meet the specific needs of their clients. With a focus on customer satisfaction, Eagle Digitizing provides custom vector art services that enhance the overall production process.

Future Trends and Considerations

As technology continues to advance, the application of embroidery services and vector art design in manufacturing is expected to grow. Innovations such as 3D embroidery and automated vector design tools are set to revolutionize the industry, offering new opportunities for creativity and efficiency. Manufacturers who embrace these trends will be well-positioned to thrive in an increasingly competitive market.

In conclusion, the integration of embroidery services and vector art design is a key strategy for enhancing productivity in the manufacturing industry. By leveraging these techniques, companies can create unique, high-quality products that meet the demands of modern consumers. As the industry evolves, staying ahead of the curve will require a commitment to innovation and a willingness to explore new possibilities.