What are the differences between embroidery and printing techniques, and how to choose?

In the world of customized apparel and merchandise, two of the most popular decoration techniques are embroidery and printing. Each method offers distinct advantages and limitations that can significantly influence the appearance and the quality of the final product. This article will explore the key differences between these techniques, helping you make a more informed decision about which method aligns best with your needs.

Embroidery Techniques

Durability and Texture

Embroidery is renowned for its durability and the classic texture it provides. This method involves stitching a design directly onto the fabric using thread, creating a raised, textured design that can withstand heavy use and frequent washing. The tactile qualities of embroidery make it an excellent choice for logos on uniforms, hats, and other items where a three-dimensional, structured appearance is desirable.

Color and Detail

While embroidery provides a rich texture, it does have limitations in terms of color and detail. Generally, embroidery uses a limited palette of thread colors. Additionally, very intricate designs may not reproduce well, as the density of the stitches can blur fine lines. For businesses relying on highly detailed logos or designs with a broad spectrum of colors, these limitations can be a significant consideration.

Printing Techniques

Versatility and Color Range

Printing has the edge when it comes to flexibility and diversity in colors. Methods such as screen printing, direct-to-garment (DTG) printing, and sublimation allow for a nearly limitless array of colors and can accommodate highly detailed images with ease. This makes printing particularly suitable for t-shirts and promotional items that feature vibrant, full-color artwork.

Printing Durability

However, the durability of printing varies depending on the chosen technique. Screen printing offers excellent longevity, often comparable to embroidery, but DTG and sublimation prints may fade over time with frequent washing. This variation in durability should be considered based on the expected lifespan of the product.

vector conversion servicesChoosing Between Embroidery and Printing

Purpose of the Product

The intended use of your product should heavily influence your choice. For corporate uniforms needing to project a professional image, embroidery is typically the preferred option due to its durability and upscale appearance. On the other hand, for casual wear or products featuring detailed and colorful artwork, printing may be the better choice.

vector art design servicesCost Considerations

Cost is another critical factor. Generally, embroidery is more expensive than printing, particularly for larger designs or those with many colors. Printing offers more economical solutions, especially for high-volume orders, making it appealing for mass production runs or events requiring large quantities.

Environmental Impact

As sustainability becomes an increasingly important concern, considering the environmental impact of both techniques is crucial. Printing, especially using newer technologies, can be more environmentally friendly with specific inks and processes that minimize waste. Again, the chosen method should align with your environmental values and the preferences of your target market.

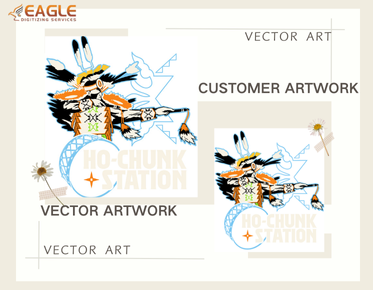

vector conversion toolEagle Digitizing's Professional Services

For those needing high-quality vector art conversion services, Eagle Digitizing provides a suite of professional offerings catering to both prints and embroidery needs. Their expertise in converting images into vectors is applicable for various applications, ensuring your designs maintain their integrity across different mediums. Their high customer satisfaction rate underscores their commitment to delivering quality results.

Looking Ahead

The textile and apparel decoration industry continues to innovate, with new technologies bridging the gap between embroidery and printing. Emerging techniques promise to enhance the qualities of both methods, offering greater flexibility in design and application. Businesses should stay informed about these advancements, balancing tradition with innovation to meet evolving consumer expectations.