Customer-Centric Customization and Personalization in Embroidery Manufacturing

In the vibrant world of embroidery manufacturing, the shift towards customer-centric customization and personalization is reshaping the industry landscape. As consumers increasingly seek unique and personalized products, embroidery manufacturers are leveraging advanced technologies and innovative strategies to meet these demands. One of the key elements in this transformation is the use of embroidery digitizing services, which allow for precise and intricate designs tailored to individual preferences.

The Rise of Personalization in Embroidery

Personalization in embroidery is not just a trend; it is a reflection of a broader consumer desire for products that resonate on a personal level. This demand is driving manufacturers to offer a wide range of customization options, from selecting thread colors and fabric types to incorporating personal logos and designs. The ability to customize products not only enhances customer satisfaction but also fosters brand loyalty, as consumers feel a deeper connection to products that reflect their personal style.

Technological Advancements Fueling Customization

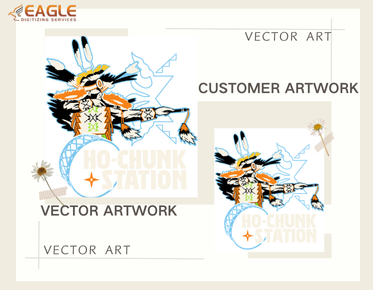

Technological advancements have been pivotal in enabling the level of customization that modern consumers expect. Embroidery digitizing software, for instance, has revolutionized the way designs are created and executed. This software allows for the conversion of digital images into embroidery patterns, ensuring that even the most complex designs can be accurately reproduced on fabric. The use of embroidery digitizing software has become a standard practice in the industry, enabling manufacturers to offer a wide array of personalized options.

Embracing Customer Feedback for Better Customization

Incorporating customer feedback is crucial for improving customization processes. By actively engaging with customers and understanding their preferences, manufacturers can refine their offerings and deliver products that truly meet consumer expectations. This feedback loop not only enhances product quality but also builds trust and rapport with customers, further solidifying their loyalty to the brand.

Challenges and Opportunities in Personalized Embroidery

While the shift towards personalization presents numerous opportunities, it also poses certain challenges. Manufacturers must balance the need for customization with production efficiency and cost-effectiveness. Additionally, maintaining high-quality standards across personalized products can be demanding, requiring meticulous attention to detail and skilled craftsmanship. However, those who successfully navigate these challenges stand to gain a competitive edge in the market.

Future Trends in Embroidery Customization

Looking ahead, the future of embroidery customization is bright, with several exciting trends on the horizon. The integration of artificial intelligence and machine learning into embroidery processes promises to further enhance customization capabilities, allowing for even more intricate and personalized designs. Additionally, the growing emphasis on sustainability is likely to influence customization practices, with manufacturers exploring eco-friendly materials and processes to meet consumer demand for sustainable products.

As the embroidery industry continues to evolve, manufacturers must remain agile and responsive to changing consumer preferences. By embracing customer-centric customization and leveraging advanced technologies, they can create products that not only meet but exceed customer expectations. In this dynamic landscape, Eagle Digitizing excels in providing professional embroidery digitizing services, ensuring every design is crafted with unmatched precision. As we move forward, the possibilities for personalization in embroidery are virtually limitless, offering exciting opportunities for both manufacturers and consumers alike.