How Much Does Screen Printing Cost?

Screen printing is a popular and versatile method for creating customized apparel and promotional items. However, understanding the cost components can be challenging. Screen printing costs are influenced by a variety of factors, such as the number of colors in the design, the type of fabric, the volume of the order, and any additional custom services required.

Factors Influencing Screen Printing Costs

Number of Colors

The number of colors in the design is a primary determinant of screen printing costs. More colors translate to more screens that need to be created, each with its own print run. Therefore, designs with many colors generally cost more compared to single-color prints. The setup cost for each screen is a significant part of the overall expense.

Order Volume

Quantity plays a crucial role in determining screen printing costs. Larger orders typically enjoy economies of scale, reducing the cost per item. Bulk orders lower the price because the setup cost is distributed across more units. Conversely, smaller orders will have a higher cost per item as the setup costs remain constant.

Type of Fabric

Different fabrics can affect printing costs due to their unique characteristics. For instance, printing on materials like polyester may require special inks or additional processing steps compared to standard cotton fabrics. This requirement can increase the overall cost.

Complexity and Customization

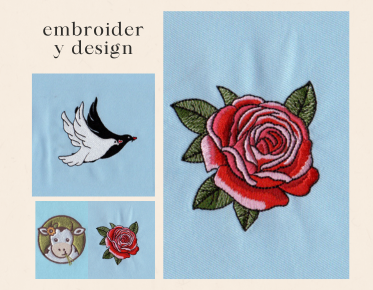

Complex designs or customized requests can increase screen printing costs as they often require additional processing, unique inks, or specific printing techniques. Customizations such as logo placement or the use of specialty inks (e.g., metallic or glow-in-the-dark) can further elevate costs.

The Role of Vector Art in Screen Printing

One essential aspect of screen printing is having the artwork in a format that can be efficiently used for creating screens. This is where vector art comes into play. Vector artwork is scalable and maintains quality regardless of size, making it ideal for screen printing. Vector art services ensure that the designs are crisp and ready for print without any loss in quality.

Cost-Effective Solutions

To manage screen printing costs better, it's advisable to work with raster to vector conversion services. These services help convert raster images into vector formats, which are essential for high-quality screen printing outputs. Many online platforms offer affordable digitizing vector services that provide quick turnarounds, adding value without significantly raising costs.

Managing Expenses in Screen Printing Projects

Streamlining Design Elements

One pragmatic approach to reducing costs is by simplifying the number of colors and complexity of the design. By doing so, businesses can significantly cut down on the number of screens required, effectively lowering the setup costs.

Choosing the Right Service Provider

Another way to optimize screen printing costs is by selecting the right service provider who offers competitive pricing and quality assurance. Companies like Eagle Digitizing provide comprehensive vector image services that include efficient conversion and meticulous attention to design detail, ensuring the printing process is smooth and cost-effective without sacrificing quality.

Future Trends in Screen Printing

The screen printing industry continues to evolve with advancements in technology and materials. Innovations in eco-friendly inks and digital screen printing offer potential cost savings and enhanced quality. By staying updated on these trends, businesses can adapt and capitalize on new methods to optimize their screen printing operations further.

As you navigate through the intricacies of screen printing costs, consider leveraging advancements in vector conversion technology to streamline your production and reduce unnecessary expenditures. Whether you are a small business owner or part of a large enterprise, understanding these factors and judiciously choosing your partners can result in substantial savings and superior final products.

What other aspects of screen printing do you find challenging, and how can we further innovate to meet evolving needs?

.png)