How Embroidery Machine Speed Affects the Embroidery Results

Embroidery is a delicate art that combines creativity with precision. One of the critical factors that can significantly influence the quality of embroidery is the speed of the embroidery machine. Understanding how machine speed affects embroidery results is essential for achieving the desired quality and efficiency in your projects.

The Role of Machine Speed in Embroidery

Machine speed in embroidery refers to the number of stitches an embroidery machine can make per minute. This speed can vary significantly depending on the machine's make and model, with some machines capable of stitching up to 1,000 stitches per minute or more. The speed at which an embroidery machine operates can impact several aspects of the embroidery process, including stitch quality, thread tension, and overall design accuracy.

Impact on Stitch Quality

One of the most noticeable effects of machine speed is on stitch quality. At higher speeds, the machine may not have enough time to form each stitch correctly, leading to issues such as skipped stitches, uneven tension, and thread breakage. These problems can result in a less polished final product, which is why many embroiderers prefer to operate their machines at moderate speeds to ensure each stitch is executed perfectly.

Thread Tension and Breakage

Thread tension is another critical factor affected by machine speed. At high speeds, the tension on the thread can increase, leading to frequent thread breakage. This not only disrupts the embroidery process but also increases the time and cost associated with re-threading and restarting the machine. By adjusting the speed to a more manageable level, embroiderers can reduce the likelihood of thread breakage and maintain consistent tension throughout the project.

Design Accuracy and Detail

Embroidery designs often require intricate details and precise execution. High-speed operation can compromise the accuracy of these details, especially in complex designs with tight curves and small elements. Slowing down the machine allows for greater control over the needle's movement, ensuring that even the most delicate parts of the design are accurately reproduced.

Balancing Speed and Quality

Finding the right balance between speed and quality is crucial for successful embroidery. While faster speeds can increase productivity, they may also lead to quality issues that require additional time and effort to correct. Many professional embroiderers recommend starting at a slower speed and gradually increasing it as you become more comfortable with the machine's capabilities and the specific requirements of your design.

Choosing the Right Machine for Your Needs

When selecting an embroidery machine, it's essential to consider the types of projects you plan to undertake and the level of detail required. Machines with adjustable speed settings offer greater flexibility, allowing you to tailor the speed to the specific needs of each project. Additionally, investing in a high-quality machine with advanced features can help ensure consistent results, even at higher speeds.

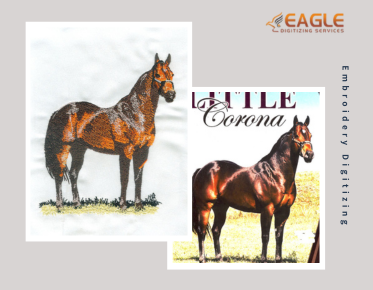

Professional Embroidery Digitizing Services

For those looking to achieve professional-quality embroidery, partnering with a reputable embroidery digitizing service can be invaluable. Companies like Eagle Digitizing offer expert digitizing services that convert artwork into precise stitch files, ensuring that your designs are executed flawlessly on any machine. With over 25 years of experience, Eagle Digitizing provides high-quality digitizing services with quick turnaround times, making them a trusted partner for businesses and individuals alike.

Future Trends in Embroidery Technology

As technology continues to advance, the embroidery industry is likely to see further innovations in machine speed and precision. Newer machines are being developed with enhanced capabilities, allowing for faster speeds without compromising quality. Additionally, advancements in digitizing software are making it easier to create complex designs with greater accuracy and efficiency.

Practical Tips for Embroiderers

For those new to embroidery or looking to improve their skills, here are a few practical tips to consider:

- Start with simple designs and gradually work your way up to more complex projects.

- Experiment with different machine speeds to find the optimal setting for your specific design.

- Regularly maintain your machine to ensure it operates smoothly and efficiently.

- Consider taking a course or workshop to learn more about advanced embroidery techniques and machine settings.

Conclusion

Understanding how embroidery machine speed affects the final results is crucial for achieving high-quality embroidery. By carefully balancing speed and precision, and utilizing professional digitizing services, embroiderers can create stunning designs that meet their exact specifications. As the industry continues to evolve, staying informed about the latest trends and technologies will be key to maintaining a competitive edge in the world of embroidery.

.png)